PRODUCTS OF THE GRP COMPOSITE INDUSTRY

GRP Pipes & Fittings is an industry itself. The size range is from DN300 to DN4000 and depending on its end-use, the manufacturing process is selected. CFW or continuous filament-winding process stands out from the other manufacturing methods in terms of speed. A DN1000 pipe can be produced at a speed of 25 meters per hour. GRP fittings are made from the pipe and cut and mitered to sizes and assembled by butt-wrapping using the same raw materials used in the pipe production. Practically all fittings can be custom-made to any project demand.

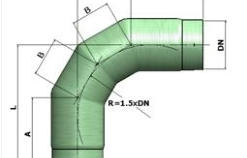

Elbows

There are 6 standard elbows: 11.25-degree, 22.50-degree, 30-degree, 45-degree, 60- degree, and 90-degree.Flanges

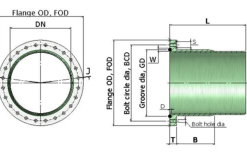

GRP flanges are made by building-up laminates to designed thickness, and boring bolt holes according to standard dimensions.

FOR THE

GRP

COMPOSITE

INDUSTRY

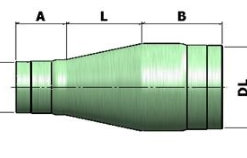

Reducers

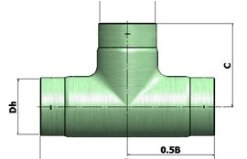

Reducers are made from standard size pipe according to the required ends and the conical portion is produced as a molded part and assembled by butt-wrapping.Tees

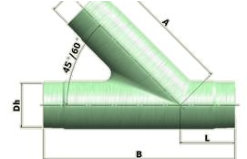

Tees are mitered from pipes and assembled by butt-wrapping.Wyes

Wyes are like tees, the only difference is the angle at which the branch is connected to the header.Pipes

GRP pipe shown in the photo above is made by CFW process with production lengths of 12 meters and are joined by a double bell coupler with reka rubber rings.

GRP Tanks

GRP Tanks are fabricated from a ribbed GRP pipe with torispherical ends of aboveground applications and hemispherical ends for underground applications.Customized Products

Equipments that are susceptible to corrosion can be fabricated from GRP using an appropriate resin. The photo above is a cooling tower.Odor-Control Vessel

GRP carbon filter shown in above photo is used to filter sulphuric fumes by passing the foul odor to an activated carbon before releasing to the atmosphere.